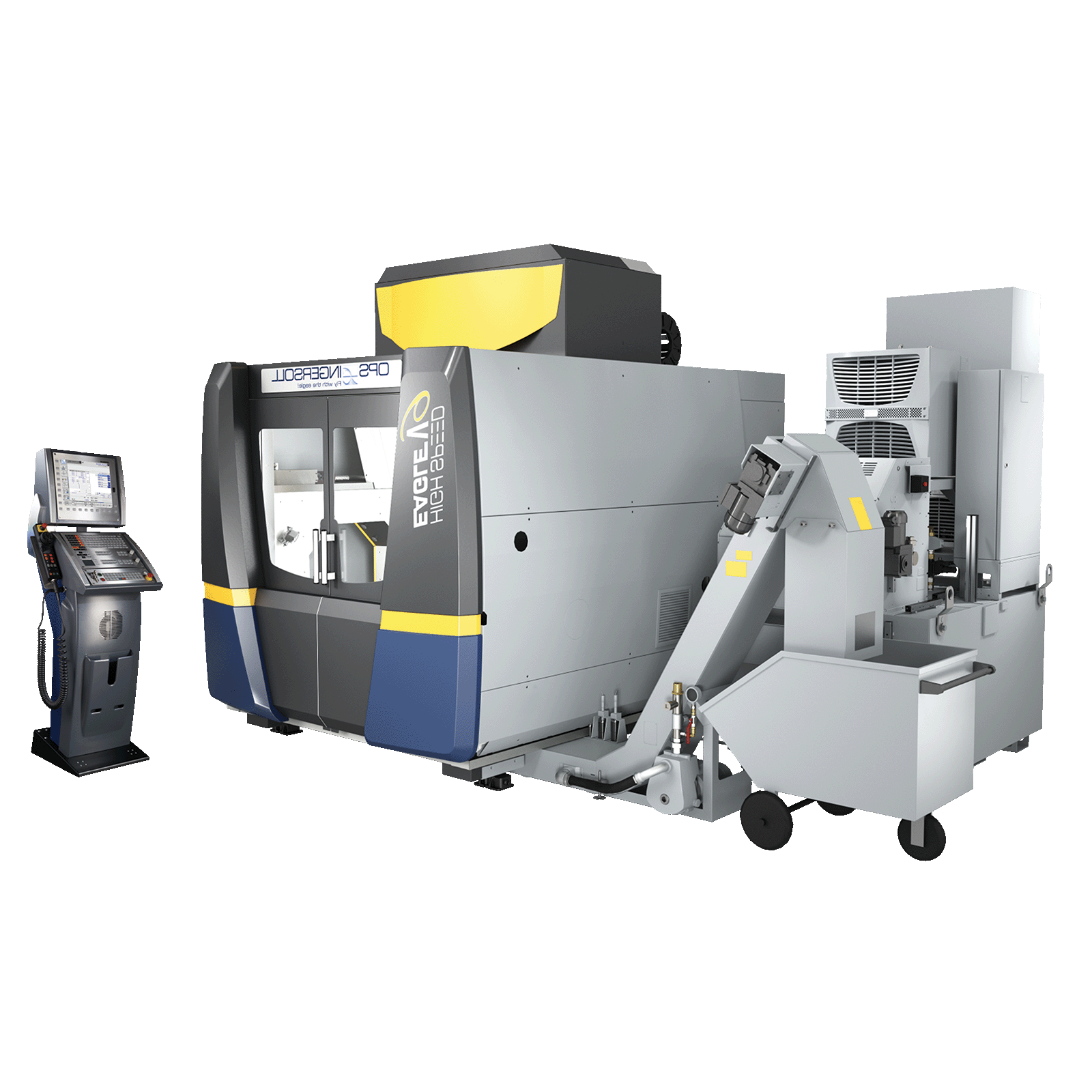

Cega sss-300 5axp

The Cega sss-300 5axp is 高精度钻孔和五轴铣削的终极机器.

CEGA SSS-300/400 5AXP的高刚性, 桥式单块结构允许高速, high-precision machining with minimized distance between the guide surface and spindle center, 提供更大的稳定性.

The high-rigidity bed with ideal rib distribution guarantees static positioning accuracy of ±0.000039”和±0.000020年“重复性. CEGA SSS-300/400 5AXP能够宽主轴转速范围(200 -30,000转) 20马力或(200 - 40,000转 7.4HP电机,采用油雾润滑主轴和长寿命交流电机. 通过干式或半干式油雾系统,可以实现高速直接硬铣.

The CEGA SSS-300/400 5AXP uses an integrated Tsudakoma 2-axis high precision Worm-Drive table with a 5.9“(150mm)直径面板 turning the CEGA SSS into a full 5-axis simultaneous micro accuracy-machining center.

The new HSK-E40 holder achieves six times higher clamping force than a regular BT shank. The CEGA SS-300 5AXP features a Fanuc 31i-B5 Super High-Speed Processor and Al Contour Control II – a “NANO CNC System” with Intelligent Velocity Control, 纳米插值和纳米平滑.

马力越大,效用越大

- The Cega sss-300 5axp combines advanced functionality with serious spindle power so you can achieve top-tier results every time.

优化您的平面图与“混合”加工

- 通过在一台机器上提供多种铣削功能, Cega sss-300 5axp让您处理更多的工作, 比以往任何时候都更经济.

跑得快,经久耐用

- The Cega sss-300 5axp combines rugged construction materials and dynamic internal components to enable continuous operation at max speed—backed up by best-in-class support from our responsive service teams.

功能:

- Ideal for both small-hole drilling and micro-fine 5-axis milling through its unique “super hybrid” design

- Allows simultaneous 5-axis control with a special design for optical encoder feedback on the rotary unit

- 达到200到30的扩展速度范围,000转, 这在一定程度上要归功于它的油雾润滑主轴和长寿命的交流电机

- The high-rigidity bed with ideal rib distribution guarantees static positioning accuracy of ±0.000023″和±0.0000039”可重复性

- Capable of 5-second tool changes, thanks to 20-position twin arm-style tool changer

- Provides both high-precision 3-axis positioning and additional 2-axis indexing accuracy

- Dual pneumatic counterbalances are located on the spindle headstock providing smooth, 高速成形和钻孔过程中Z轴的精确运动

- Built to jig-grinder standards of quality and accuracy with bridge construction that eliminates the X axis table overhang commonly associated with C-frame construction designs

- 提供优良的冲击和振动阻尼高速, 高精度加工,更大的稳定性 via high-rigidity structure and Meehanite GC castings for both the base and bridge

- New tool measurement device location “Blum 激光” is relocated to an out-of-stroke position

- 具有增加的传送门高度(5).9“/150mm)用于添加A/C轴单元

组件:

- 高刚性Meehanite结构

- Tsudakoma rt - 261高精度零间隙数控倾斜/转台

- 津田驹2轴高精度工作台配有5.9“(150mm)直径面板

- 高刚性HSK-E25刀柄, allowing 6x higher clamping force than a regular BT shank for highly reliable work

- NC option package for 5-axis machining with high-speed tool center point control

- 滚柱式直线运动方式

- Z轴热生长补偿

- 非接触式工具测量(Blum激光),空气吹洗

- 双Z轴平衡气缸

- 80加仑冷却液罐标准

- A/C轴光学旋转编码器反馈系统

- X, Y, Z轴线性尺度

- 7加仑油箱的主轴冷水机

用户界面:

- Fanuc 31i-B5超高速加工, 纳米平滑, AI等高线控制II, 和NANO插值

- 5轴机床数控选项包

- 高速平滑TCP

- 刀具中心点控制

- 光滑的TCP

- 工具姿态控制

- 扩展了刀具中心点控制中的轴线移动命令

- 倾斜工作平面命令

- 三维刀具补偿

- 倾斜工作平面分度的多个命令

- 刀轴方向控制

- 5轴机床参数设置扩展

- 公差控制

- 1000块前视块扩展

- 超级PC III功能,具有3模式操作,以平衡速度和准确性

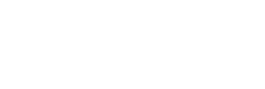

| 机器行程:X X Y X Z in (mm) | 20.1 x 16.1 x 12.2 (510 x 410 x 310) |

|---|---|

| 主轴转速 | 200 ~ 30000转/分 |

| 主轴惠普 | 20.0 |

| 主轴润滑 | 油雾 |

| 换刀器尺寸 | 20岗位标准 |

| 定位精度/重复性:in (μm) | ±0.000039” / ±0.000020” (±1.0 / ±0.5) |

| 转盘面板:in (mm) | Ø 5.9 (Ø150) |

| 马克斯. 倾斜a轴角度:度. | -110 ~ +30 |

| 回转c轴指标精度 | ±4.0弧秒. |

| 倾斜a轴指标精度 | ± 4.0弧秒. |

| 面板到主轴机头距离:in (mm) | 1.85 ~ 14.05 (47 ~ 357) |

| 马克斯. 工件重量:lb (kg) | 20 (44) |

| 冷却液罐容量:加仑(L) | 80 (300) |

| 面板距地面高度:in (mm) | 39.5 (1003) |

| 实际测量圆度(4.0”迪亚. @8 IPM): in (μm) | 0.000044 (0.11) |

| 主轴锥度 | HSK-E40 |

| 主轴空气吹扫 | 标准 |

| 经主轴吹风 | NA |

| 带收集器的油雾 | 可选 |

| 线性尺度X, Y, Z轴 | Heidenhain 0.000002毫米标准 |

| 快速遍历速度:in/min. (米/分钟.) | 590 (15.0) |

| 切割速度(普通模式):in/min. (毫米/分钟.) | 0.04 – 394 (1 ~ 10,000) |

| 切割速度(GR Super PC模式):in/min. (米/分钟.) | 590 (1.5) |

| 集尘系统 | NA |

| 机器重量:lb (kg) | 12,125 (5,500) |

| 机器高度:in (mm) | 106.0 (2690) |

| 所需占地面积:单位:mm | 91.5 x 100.4 (2,325 x 2,550) w冷却剂冷水机选项 |

| 控制单元 | Fanuc 31i-B5 Super High-Speed Processor, Al Contour Control II and 5-Axis machining package |

| 功率要求KVA | 200 ~ 220vac: 32.0 kva |

| 空气供给 | 17.5 cu.ft./min≤72 psi |

概述

- High-rigidity structure using Meehanite GC castings for both the base and bridge providing excellent shock and vibration dampening for high-speed, 高精度加工,更大的稳定性

- Built to jig-grinder standards of quality and accuracy with bridge construction that eliminates the X-axis table overhang commonly associated with C-frame construction designs

- 增加传送门高度(150mm.9英寸)用于添加A/ c轴单元

- Ultimate fusion of high-precision 3-axis positioning and additional 2-axis indexing accuracy

- Simultaneous 5-axis control with special design for optical encoder feedback on rotary unit

- Wide spindle speed range using an oil-mist lubricated spindle and a long-life AC motor

- New tool measurement device location “Blum 激光” is relocated to an out-of-stroke position

- Dual pneumatic counter balancers are located on the spindle headstock providing smooth, 高速成形和钻孔过程中z轴的精确运动

特性

- 超级混合概念-小孔钻孔和微细5轴铣削

- 高刚度米汉体结构

- 滚柱式直线运动方式

- 扩展主轴转速范围- 200至30,000转或200 - 40,000转

- z轴热生长补偿

- 7加仑油箱主轴冷水机

- 高刚性HSK-E40刀架

- 非接触式工具测量(Blum激光)与空气吹洗

- 双z轴平衡气缸

- X, Y, Z线性尺度

- Tsudakoma rt - 261.零隙蜗杆驱动数控倾斜/转台

- A/ c轴光学旋转编码器反馈系统

- 20位双臂式换刀器,5秒换刀(60秒. 可选)

- 60位置AHC(自动工作支架更换)可选(使用3R-600.86-30宏卡盘)

- 80加仑标准冷却液罐

- 超级MAC II-ac功能使用雷尼绍OMP400触摸探头(可选)

- Fanuc 31i-B5超高速处理, 纳米平滑, 人工智能轮廓控制II和纳米插值

- 1000块前瞻块扩展

- 超级PC III功能与3模式操作平衡速度和准确性

- NC Option Package for 5-Axis Machining with High-Speed 工具 Center Point Control

相关解决方案

-

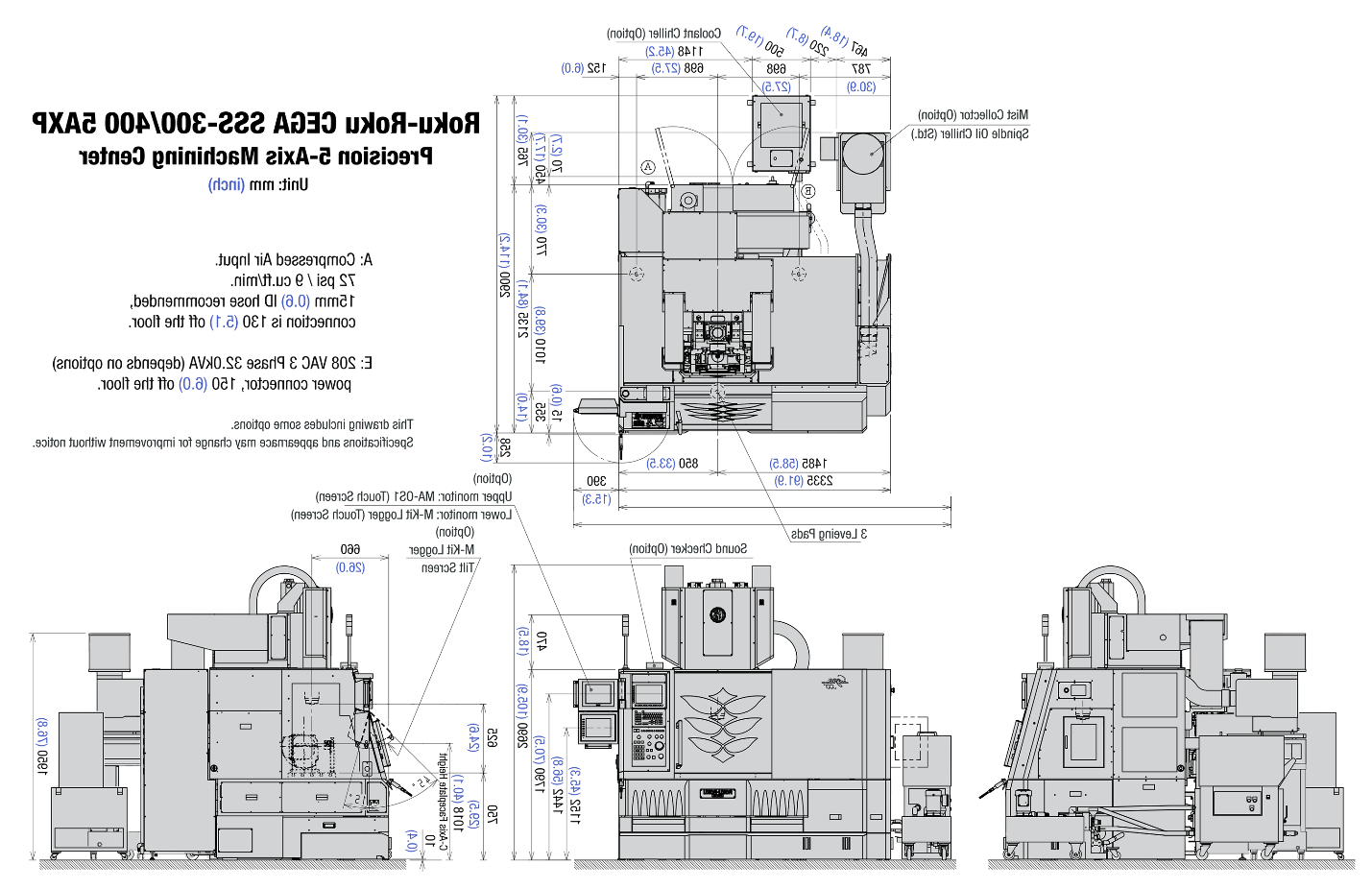

五轴加工技术

高速, high-precision machines with the power and flexibility to meet any challenge.

了解更多 -

直线驱动技术

Hyper-准确的 machinability for tight tolerances and micro-fine work where the details really matter.

了解更多 -

高速加工

Top-of-the-line machinery with added cooling power for consistent performance on mission-critical tasks.

了解更多 -

石墨制造

制造石墨电极的多种解决方案和专业知识.

了解更多 -

铣削自动化

制造石墨电极的多种解决方案和专业知识.

了解更多

-

"Not only does the 5-axis capability of the OPS Ingersoll Eagle V5 milling machine enable us to burn parts with less physical electrodes, it also has a robotic tool changer so we can focus more during the day on things that need constant attention."

布拉德·麦克道尔, 质量工具 & 死的总统 阅读案例分析 -

-

"The Eagle 800 has burn technology that gives us a competitive advantage because it takes about half the time to burn and uses fewer electrodes, 这样既节省时间又节省金钱. bt365体育娱乐的目标是整天和整个周末都跑. I like that we also are cutting down on our carbon footprint by using fewer graphite electrodes and less copper wire than before."

史蒂夫(, 零容忍总统 查看案例研究 -

-

-

"The kinematics of the Roku-Roku VMCs allow us to run faster feed rates and not sacrifice surface finish or accuracy. 这些机器在增加刀具寿命方面效率很高, 可靠的发那科控制和整机稳定性. We can run longer intervals on downstream inspection on parts that the Roku-Rokus machined."

约翰TerBeek, 特贝克模塑公司的合伙人 & 工具 查看案例研究